Solar Well Pump Systems, A Complete Overview

The following article describes the major components of a solar powered well pump system. These are very simple systems, capable of replacing most utility connected wells. They are capable of pumping water from hundreds of feet underground at many gallons per minute. With a mere 6 hour of sunlight a day, these systems are capable of producing thousands of gallons of water every day, all without being connected to utility provided power. Now more than ever before, solar well pumps can replace hard wired systems.

Basic Solar Well Pump System Components

All of our solar power well pump systems consist of three main components as well as a bunch of other smaller parts to help you assemble the system on your own.

- Brushless DC Well Pump

- Maximum Power Point Tracking(MPPT) Controller

- Solar Panel Modules (if purchased as a complete kit)

Brushless DC Solar Well Pump

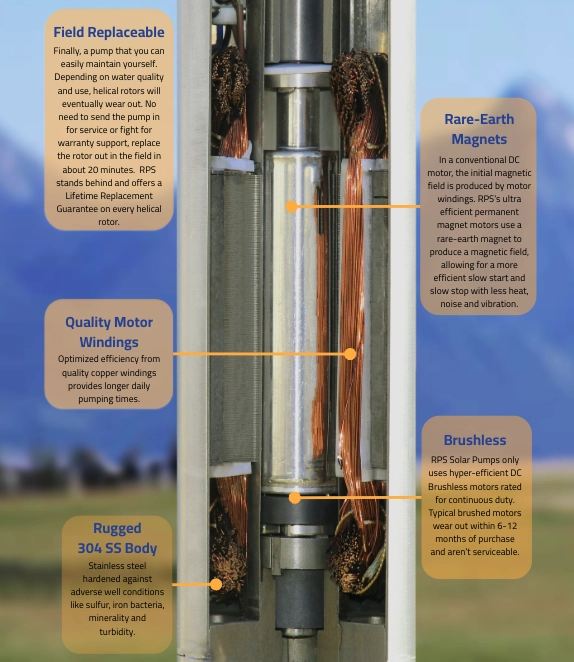

Brushless DC solar well pumps are made up of two main parts, the brushless DC motor and the pumping mechanism. The brushless motor takes electrical power and converts it into mechanical energy, which provides the force required to turn the pumping mechanism. This mechanism pumps water causing it to rise from deep beneath the ground to the surface, hundreds of feet above.

The brushless well pumps we carry are designed to operate on solar power. They features a highly efficient brushless DC motor designed for years of use. Brushless technology is the latest advancement in DC motors. Brushless motor technology increases the energy efficiency and decreases the required maintenance, since there is no need to change carbon brushes which wear down over time in standard brushed DC motors. Brushless motors have no brushes, hence the name, and are designed for many years of continual usage without maintenance.

The second major pump component is the pumping mechanism. Our pumps feature a helical rotor pumping mechanism. This consists of a stainless steel spiral mechanism, which spins against a rubber gasket. This spinning motion against the gasket, forces water upward and out of the well. The pumping mechanism is user replaceable in the field. All of our pumps come standard with a spare, so the user never has to worry about pump down time. Simply remove three screws on the top of the pump, remove the old pumping mechanism and insert in the new mechanism. Unlike other designs, there is no need to send your pump back to the factory for costly repairs if pumping efficiency decreases.

The body of the pump is made out of 100% stainless steel. Stainless steel is a hygienic material perfect for drinking water applications. The other benefit of stainless steel is that there is no need to worry about the pump rusting or corroding. The pump is designed to offer years of maintenance free service.

Maximum Power Point Tracking Controller

The maximum power point tracking (MPPT) controller is the brain of the entire system. It takes power generated from the solar panels and supplies it to the brushless DC motor. At the same time it monitors solar panel performance and makes adjustments as needed to the voltage and current in order to maintain maximum performance. Other inferior systems use brushed DC motors connected directly to solar panels. These systems waste energy since they are not operating at their maximum potential power. The MPPT feature improves overall system efficiency, especially in low light, overcast conditions.

The MPPT controller also features low well shutoff and storage tank overflow sensors. If the well starts to run dry, the controller will shut off the pump in order to prevent damage to the motor. The pump should never be run dry due to a drop in the water level, and doing so for even a few seconds can damage both the motor and pumping mechanism.

The storage tank overflow sensor will shut off the pump once the storage tank is full. It is a very simple float that is installed in the top of the storage tank to sense when it is full. Stainless steel probes may also be used instead of the float valve. Once full, it sends an electrical signal to the controller to shut off the pump. This is a very useful feature to prevent pumping of water when the tank is full and starting to overflow onto the ground. There are two benefits to this feature. First, water is not wasted and pumped onto the ground. Second, operating life of the pump is extended, since it is not running unnecessarily.

An alternative to using the tank overflow sensor is to utilize the motor speed setting on the MPPT controller. This consists of a simple dial which can adjusts the speed of the pump. All of our controllers feature a digital speed controller which regulates the speed at which the pump operates. The pump can be set to operate at any speed desired and can be fine-tuned to the amount of water needed on a daily basis. If the full flow rate it too much, it can easily be adjusted to any lower flow rate by a simple adjustment of the regulator.

The MPPT controller is encased in a water resistant enclosure and is suitable for outdoor use. It features water resistant wire pass-through ports on the bottom, to prevent both moisture and bugs from entering the electronics. Power and external sensor connections are made easy by the use of clamping screw terminals. Only a screwdriver is required to make the electrical connections to the controller.

Solar Panel Modules

All of the solar panels provided in our well pump systems are mono-crystalline silicon panels. Mono-crystalline cells provide maximum performance in the smallest area. Last generation technology, amorphous silicon, does not provide the same area to power performance. We have chosen to use the latest technology of solar cells in order to provide maximum performance for each system.

The cells are connected as necessary to achieve proper voltage and current for each module. The modules feature industry standard MP4 connector for ease of making series and parallel connections to increase system power. There is no need to splice wires in order to make these connections. The MP4 connectors are water resistance and ideal for an outdoor environment. Every panel has an aluminum frame and tempered glass to protect the solar cells. The tempered glass is impact resistant to prevent damage in severe weather conditions.

All of our solar panel systems are sized to at least 1.6 times great than the pumps power requirements in order to maintain performance in low light conditions. If you choose to purchase solar panels separately or have your own solar panels, we recommend a minimum of 1.4 times panel to pump power ratio. All of our panels range from 80 watts to 100 watts as necessary to achieve proper current and voltage. We tend to use the smaller solar panels since they are easier to ship and install by a single person. If solar panels are sourced locally, our systems can use any size modules as long as the current and voltage are correct.

Recent advances in solar panels have really made these small scale systems possible. High quality low cost panels can be produced in module form. This means all solar cell connections are made at the factory and encased in protective glass and a rugged aluminum frame. Only two power connections exit each module with easy to use MP4 connectors. Series connections can be made easily with just the existing module connectors. Parallel pigtail connections are provided as needed to connect panels in parallel. This makes the solar panel electrical connections very easy to make.

Conclusion

Now is a better time than ever to install a solar power well system! The technology has advanced to a point where system performance exceeds the requirements for large variety of usages. From homes to farms, there is a cost effective solar well pump solution available. Check out our available systems and as always please feel free to contact us for personalized assistance in choosing a system.