Submersible Pump Plumbing

Drop pipe (n) The plumbing (pipe or tubing) that carries the water up from the submersible pump to the surface

Rigid pipe vs. HDPE ‘black poly’ pipe

Traditionally wells have been installed with rigid pipe. First it was galvanized steel pipe (heavy and difficult to install without a boom truck as each 20’ length needs to be suspended and screwed together). Next rigid PVC replaced steel, being much lighter and partially flexible, but still needing to be screwed together in 20’ lengths.

The down side of both kinds of rigid pipe is that most of the time, a well owner will need a well pump professional or someone with a boom truck to pull their well pump, leaving them beholden to a contractor to help them. The magic of poly pipe is that it can be installed easily by one or two people depending on the depth of well; it’s lighter, can be dropped by hand, and doesn’t corrode in your well. It gives the customer control over their well.

Pipe length, diameter, and pressure ratings

Most people set their pumps 20-30’ below the water level. If you know your well is a good producer and won’t drop down at the pumping rate, then you can go even shallower. If you have a really slow recharge rate on your well, we recommend going the full 80’, which is the maximum allowable submersion depth for these pumps. For the water volumes of most of our kits, we recommend 3/4” pipe. As frictional losses increase with gallons per minute and distance, usually only so when 15 gpm or greater, so while some people prefer 1” pipe to 3/4”, it doesn’t really gain you much for our systems. If traveling 300 or more above ground, 1”+ is more ideal generally. Here is great link for Pressure drop due to Frictional loss calculations.

We do recommend at least 160 psi as it is more rigid-walled and doesn’t kink as you work with it. Over 160 psi is fine, too, it’s just heavier and needs to be heated up more with a heat gun when using barbs and hose clamps.

|

Frictional head loss over distance of poly pipe* |

|||||

|

Diameter |

|||||

|

Length |

1/2” |

3/4” |

1” |

1-1⁄4” |

1-1⁄2” |

|

100’ |

20’ |

5’ |

1.7’ |

0.5’ |

negligible |

|

500’ |

NR* |

27’ |

8.5’ |

2.3’ |

1.1’ |

|

1,000’ |

NR* |

54’ |

17’ |

4.6’ |

2.2’ |

|

The amount of total pump head (shown in feet) increases due to friction over long horizontal distances of poly pipe depending on the diameter of the pipe. Smaller diameter pipe adds more head to the system. *Calculated using an average flow of 5 GPM at 70°F |

|||||

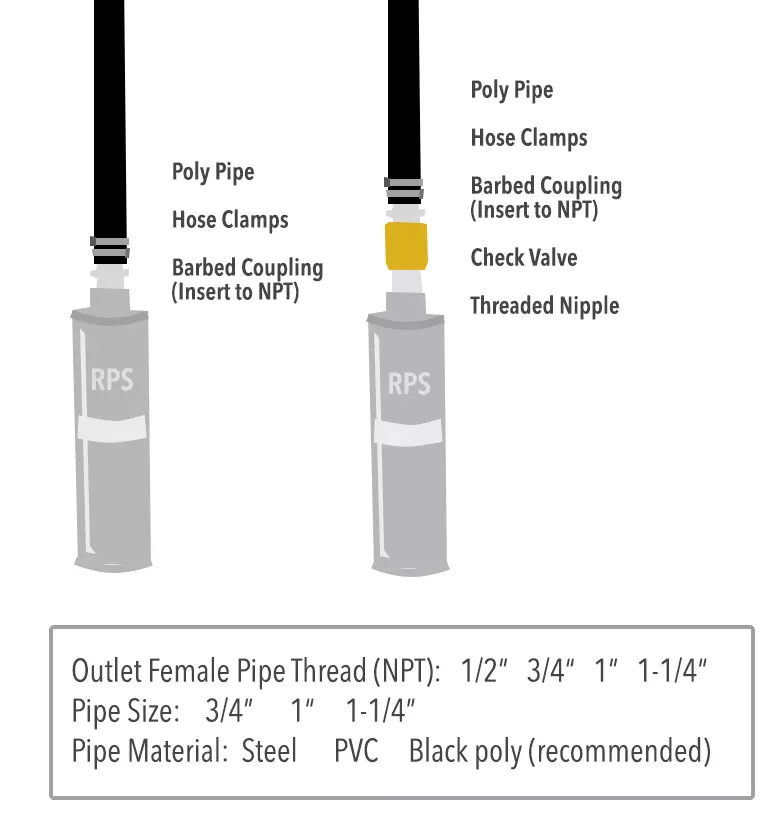

Getting a tight seal with poly pipe on a barb coupling

To make the tightest connections possible between your barbed coupling and your length of poly pipe, it is best to apply even heat from a heat gun or a lighter (if you’re careful!) to warm up the poly pipe so it’s more malleable to fit snugly over the barb, and for the hose clamps to tighten more firmly around the barb.

Tip: use a socket set on the hose clamps instead of a flathead screwdriver for a tighter fit.

Do I need a check valve?

If you are doing a pressure system or pressure shutoff then the answer is always yes. The pump has no check valve and one is required to build pressure. If you have a really long run on the surface then adding one just above the pump is ideal. If just going into a storage tank at the well head, then often customers do not add one as it allows water to drain from the drop pipe and prevent freezing above ground. Freezing is another topic outlined on the site but general letting the water drain back is the most foolproof system without a check valve.

How deep should I place my pump?

This depends on the productivity of the well generally and on the water volume you want to pull each day. Lower producing wells usually drawdown more so lower pump set is ideal. If you have a high volume (GPM) rated well you can get away with only 20 feet below the surface. Your system comes with a low water shutoff to prevent the pump from running dry as well.