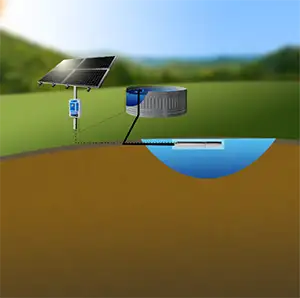

Solar Pump to Pressure Tank and Cattle Waterer

Solar Well Pump | Pressure Shut-off | Pressure Tank | Livestock | Waterer

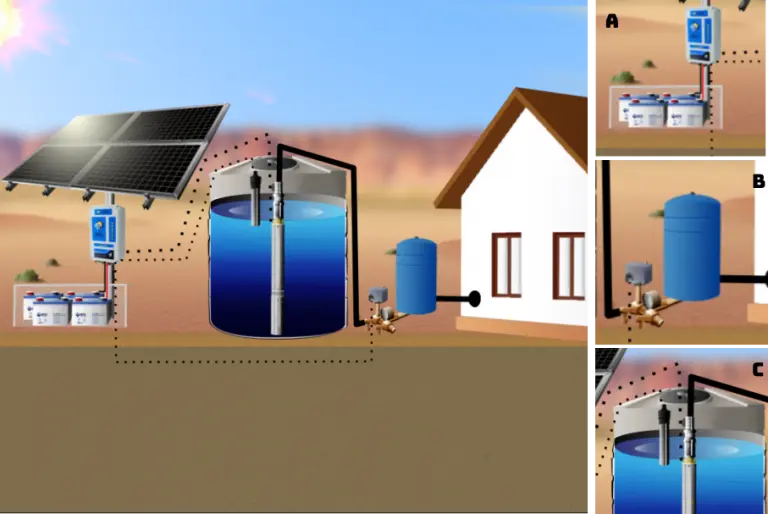

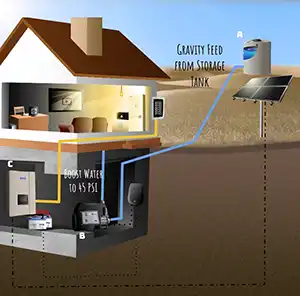

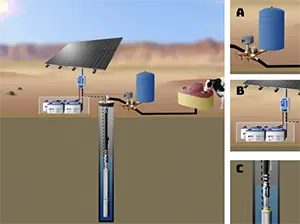

This install is especially good for cold climates, long runs or sites where there is already trenched pipe, and for cattle waterers that need pressurized water. Popular automatic waterer brands include Richie and Mirafont. Instead of the normal wire and tank sensor, this install uses pressure to turn the pump off and prevent overpressuring your plumbing. (Comparable to a mechanical float valve in an open tank or storage tank) Because we are building pressure you’ll need a check valve (C) installed on the pump. Near the well head you will also need a tank tee (pressure tank optional to reduce cycling) with a reverse action pressure switch (A) Since the system is installed with batteries (B) to allow for 24/7 water pressure, the tanks and waterers are kept full no matter the season.

Check out our Customer Installation Story of a rancher in Pennsylvania using automatic waterers for his RPS 400 winterized set up.

Customer Question:

My solar pump is connected to a storage tank a few hundred feet away from the well head. I do not want to run a tank full sensor wire and instead would like to use back pressure in the piping to shutoff the pump.

I am thinking about using a float valve on the water tank and a pressure switch back at the well head to turn the solar well pump on and off. When the float valve closes, due to the tank being full, the pump will create pressure in the line and shut off the system.

This way I do not have to run additional sensor wires for the high water shutoff. Do you have any ideas or thoughts on this system?

Answer:

Yes, this is a very common setup. A float valve and pressure switch is a great way to eliminate having to run additional sensor wire. In essence, you are using the piping as a signal to turn off the pump.

The pressure switch can be connected directly to the tank full input on the controller, but a “reverse action” type pressure switch is needed. These are opposite of the standard action switches used on AC pumps. They are normally open (pump operating) and close when the high pressure is reached.

Closure of the switch will cause the well pump controller to shut off the pump. When the water level drops in the tank and the pressure in the line is released, the pressure switch will go open and the controller will start the pump again.

It will require a little bit of tweaking of the pressure settings to get the system operating consistently and prevent pulsing of the pump due to the float valve bobbing up and down. A vertical piece of PVC pipe off a T and capped at the end can be used as an impromptu air bladder tank. This adds a bit of pressure buffer to the system and can help prevent pulsing of the pump.