Well to Faraway Tank (2,000 Feet!) Using a Pressure Shut Off

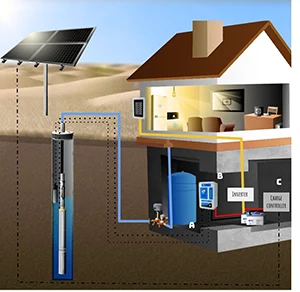

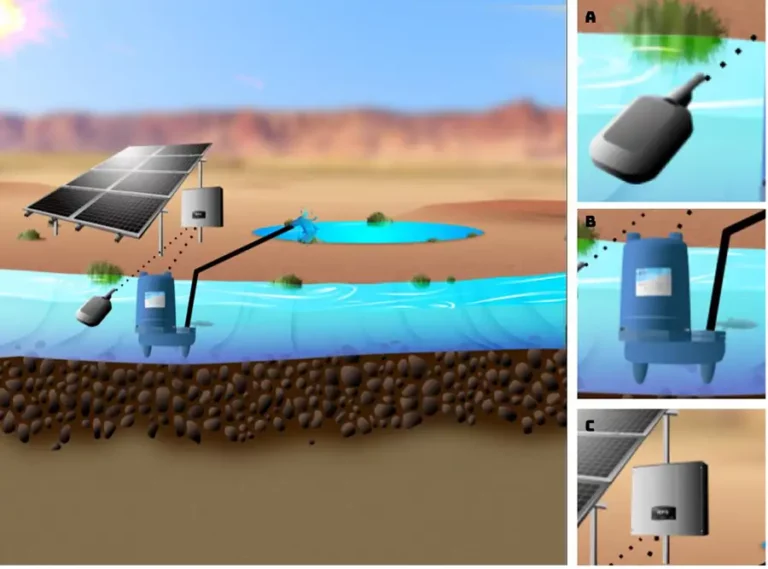

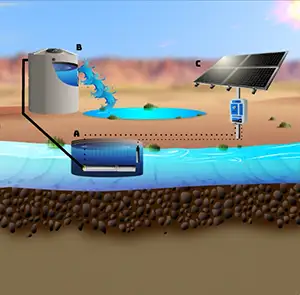

The RPS universal charge controller (B) is the brains of the operation. Solar power from the panels is routed through the controller to the pump using an MPPT for maximum efficiency. Sensors reacting to environmental conditions that turn the pump on or off for protection are also connected. We use a wet/dry tank full sensor wired directly to the controller. In the diagram there is a wet/dry sensor above the pump, shutting the system off to prevent damage from running dry. If a tank is significant distance away from the well and controller, a pressure shut off system is used instead of a tank full sensor at the top of the tank. Using a pressure shut off saves you the hassle and cost of trenching hundreds or even thousands of feet of wire. A check valve is attached directly off the pump to help build pressure in the line and maintain prime, a reverse action pressure switch (C), senses whether the mechanical float (A) is opening or closing the line. If the mechanical float has closed the pipeline it means the tank is full and the reverse action pressure switch sends a signal to the controller to turn the pump off. If the mechanical float has dropped and the pipeline is open, the reverse action pressure switch sense the drop in line pressure and tells the pump to turn on. As you can see, the reverse action pressure switch is hardwired and connected to the charge controller by two 18 gauge wires.