Solar Well Pump Winterization

Solar Well Pump Winterization Tactics for Harsh Winters

As the cold season approaches, safeguarding your solar well pump from the harsh elements is vital. Winterization of your well will protect your investment and ensure reliable operation, even when temperatures plummet.

When discussing the right type of winterization for you it depends on if you plan on using your pump throughout the winter, or if you are planning on keeping your well active during the cold months.

If you are in an area that tends to reach or has ever had freezing temperatures, you should make every effort to prevent your pipes, well, and well components from freezing. When pipes freeze, the flow of water is completely blocked. Since water expands as it turns into ice, the pipes are very likely to burst. It could also ruin your well pump and other exposed well components.

Key Facts:

- It’s important to note, that as many people who have trenched pipe know well, frost does not penetrate very deep into the ground. Soil temperatures at well-depth typically stay above freezing all winter long. Therefore, it is not the well water you need to worry about, but rather the water that travels through the pipes.

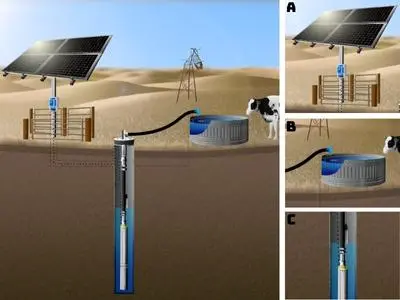

- Well water pumps located below the Static Water Level are not susceptible to freezing. However, surface pumps could be at risk if it is not properly protected.

- If your wellhead is exposed to outside elements and freezing temperatures are on the way, wrap it with insulation, blankets, towels, or anything else you can find that will not cause damage to the wellhead but can help protect it from the cold.

- PRO TIP: Water tanks are also vulnerable to freezing and should be inside an insulated enclosure. If you are in a warmer climate your pump and tank may be outside. If your pump and tank are exposed and your area experiences unexpected days of freezing temperatures, wrap them with insulation, blankets, towels, or anything else you can find that will not cause damage to these components.

At What Temperature do Pipes Freeze?

Freezing can take place at temperatures as low as 20°F (-6°C) or lower. The exact temperature at which pipes will freeze depends on various factors, including the type of material the pipes are made of, the insulation of the lines, the velocity of the water flowing through the lines, and the surrounding air temperature.

What is a Frost Line?

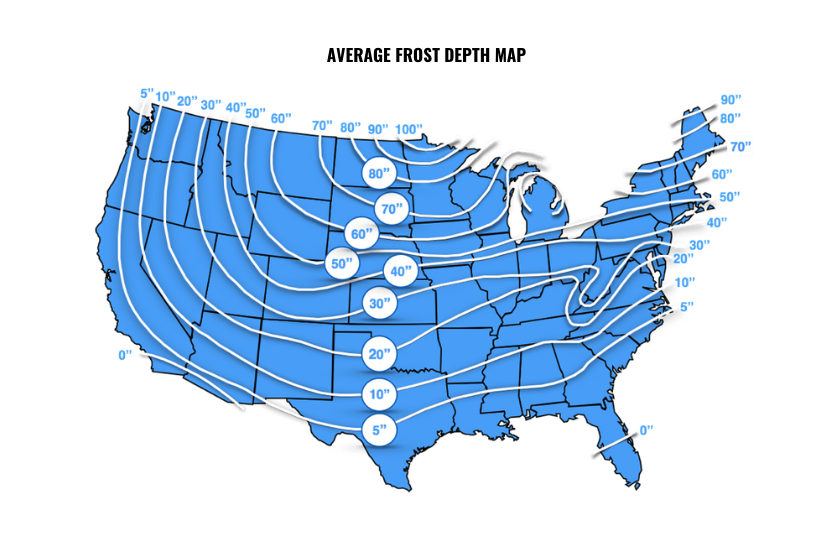

The frost line is the average depth that the ground freezes every year. The more severe the winters, the deeper the freeze, and the deeper water pipes and cement footings need to go. Also known as ground freezing depth, the frost line extends from the top of the soil to an average depth but thaws out during the warmer months.

Why is Meeting the Frost Lines Important?

As water freezes, it expands. If you’ve ever forgotten a can of soda in the freezer, it will swell and burst. It’s the same with water and sewer pipes buried above frost line depths.

Above the frost line, the ground can heave up, shifting whatever is in it, or freeze the pipes’ contents. To avoid these issues, knowing the frost level in your area allows you to construct below the ground freezing depths to keep pipes flowing, decks level, and foundations stable.

Protecting Your Solar Well Pump When Not in Active Use

Covering Solar Panels:

To prevent snow accumulation from damaging your solar panels, it’s essential to cover them. A sturdy, weather-resistant cover will keep the panels clear of snow, which is particularly important if you’re not using the system during the winter. Additionally, make it a routine to brush off any excess snow to maintain their condition for when you need them next.

Unplugging Controllers:

Your system’s controllers are the brains of the operation. To avoid any potential cold weather damage, disconnect them and store in a dry, secure place until they’re needed again. This simple step can save you from unnecessary repairs or replacements.

Storing Surface Pumps:

For surface pumps, winterization means disconnection, thorough cleaning, and storage in a dry area. This prevents any residual water from freezing and causing internal damage, ensuring your pump is ready to perform when spring arrives.

Handling Pumps in Shallow Waters:

If you have submersible pumps in ponds or creeks, remove them before the freeze sets in. Dry them out completely and store in a non-freezing environment. If it’s not possible to dry them, submerge them in a bucket of water in an area that won’t freeze, like a heated garage.

Maintaining Continuous Operation Through the Winter

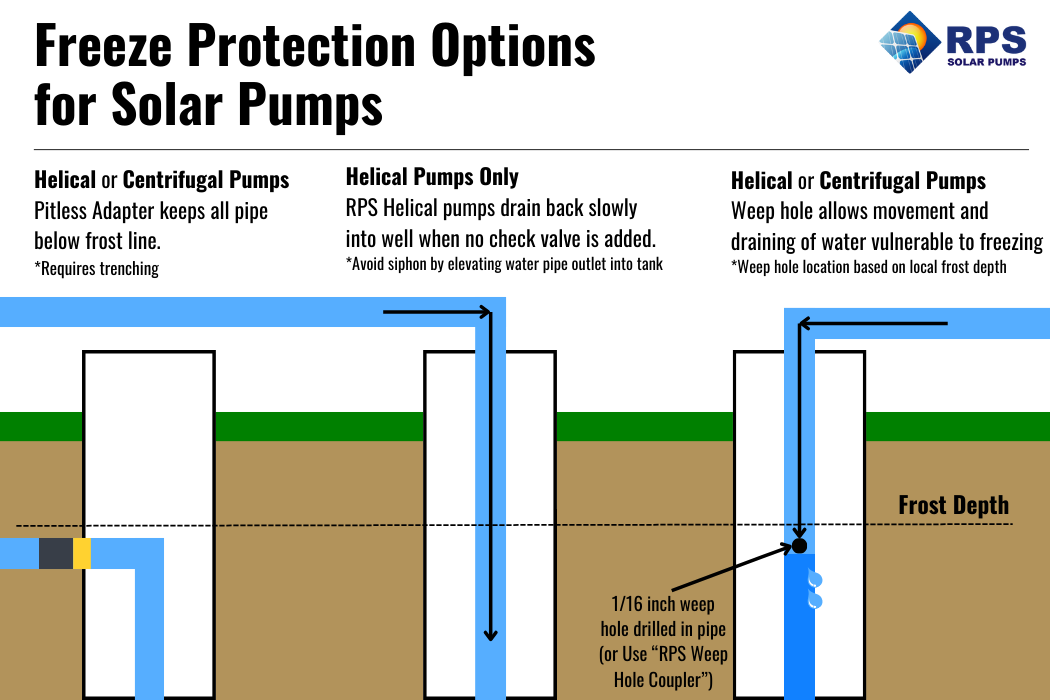

Utilizing Pitless Adapters:

A pitless adapter is your first line of defense for keeping the water flowing below the frost line. By facilitating a direct, below-ground connection, these adapters keep the water from freezing, ensuring continuous supply without the need for a well pit.

Draining Back Water:

For RPS 200 through 800 helical models, implement a drain-back system that allows water to retreat back into the well when not in use. This solution means no water remains in the pipes to freeze overnight.

Check Valve Considerations:

Ensure your system is set up without a check valve if you’re using a drain-back system. This allows for the water to freely move back into the well, eliminating the risk of frozen pipes.

Proper Pipe Outlet Height:

Position your pipe outlet above the highest water level in your storage tank to avoid siphoning. This ensures that the drain-back system functions correctly and prevents freezing.

Adding Weep Holes:

In pressurized systems, install a weep hole below the frost line on your drop pipe. This small modification allows trapped water to escape and prevents ice from forming in your system. It is important to note, however, that adding a weep hole to a pressurized system will cause the pump to cycle as pressure can never truly be held in the pipe. At that point you’d need to decide whether to use a pitless adapter or just not use the system in winter.

Advanced Winterization Techniques

Insulating Pipes and Components:

Insulation is key for any exposed piping. Use high-quality foam or fiberglass insulation to wrap your pipes, protecting them from freezing temperatures. Don’t forget to insulate the pump itself, which can be done using specially designed pump covers or blankets.

Electrical Component Care:

Shield all electrical components, including controllers and sensors, from the cold. Use waterproof covers and insulating materials to keep moisture out and warmth in.

Battery Maintenance:

For systems with batteries, charge them fully before the onset of winter. Store them in a place where the temperature remains constant and above freezing. If they must stay outdoors, insulate them well to prevent loss of charge or damage.

Regular Inspections:

Even during downtime, periodically inspect your system. Look for signs of wear, check the insulation integrity, and ensure that solar panels, if uncovered, are clear of snow and debris.

Adhering to Manufacturer-Specific Instructions

Manufacturer’s Instructions:

Always refer to your solar well pump’s manufacturer guidelines for tailored winterization procedures. Each model may have unique requirements that are critical for proper winter care.