What is the difference between a regular electric pump and a solar water pump?

Today’s question is, “What is the difference between a regular electric pump and a solar water pump?” So in the USA, your electric pump is either going to be running at 110 volts AC or 220 volts AC. If you have a smaller pump, usually one horsepower or less than it might be running off of 110 volts. For 220 volts, you can go all the way from a 1/2 horsepower up to around 7 1/2 horsepower.

So if you have a larger pump, then most likely it’s going to be running off of 220 volts. You can go inside your electrical breaker panel and see where your pump is hooked up. If it’s hooked up to a single breaker most likely it’s running on 110. If it’s hooked up to two breakers, then it’s most likely it’s running on 220 volts.

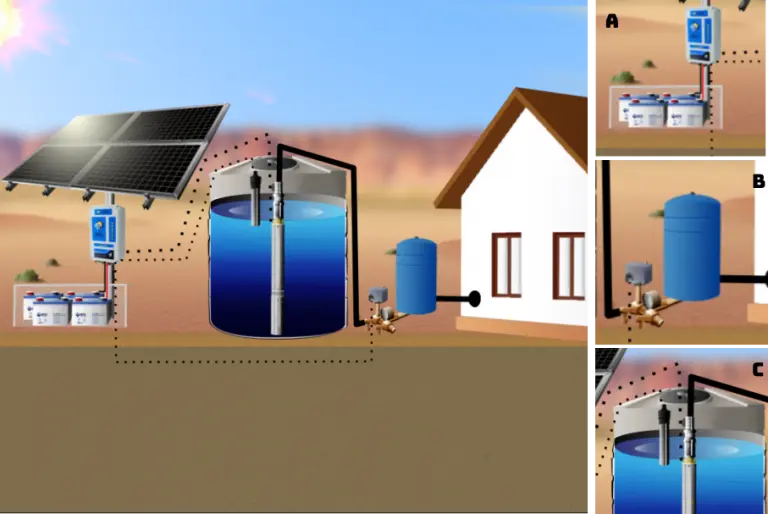

For a solar pump, there’s a couple of different power options. For smaller systems, they’re going to run in the lower DC voltage range of anywhere from 24 up to 48 volts. When you get to larger systems, they’re going to be using more of an off-the-shelf type of pump. We’re going to pair that with a controller that can convert high voltage DC and drive those pumps.

Normally, those are three-phase pumps that we operate. It kind of works like a variable frequency drive and takes that solar power and operates that pump off of it. So with the smaller solar pumps, we have our RPS200 through our RPS800. Those are operating at that lower voltage range, anywhere from 24 up to 48, sometimes 72 volts if it’s slightly higher power. When you get to our Pro Systems, then that’s using those three-phase AC pumps and we have our Pro Controller that’s going to take the power from our solar panels and drive that pump.

Next, let’s talk about how the actual motor itself is constructed. So with an AC pump, it has windings: those are the copper windings that create the magnetic field on both the rotor and stator. So the stator, that’s the outside windings, that’s gonna be on the outside of the pump, and that’s going to start to create the magnetic field. On the inside, on the rotor on a classic AC pump, it’s also wound with wire. That’s called an induction motor. That’s going to be slightly less efficient than we’re looking at with the brushless motor

counterpart. So for a majority of our solar pumps, we use what’s called a brushless motor.

So again, on the outside, on the stator, we have the copper winding, but on the inside, on the rotor, we choose to use high quality permanent magnets. In that case,

we’re going to be more efficient. So that means for every watt we put into the system, it’s going to pump slightly more water. That’s very important that we’re using a solar pump because we want to maximize the water produced based on the amount of sunlight available.

Another great feature of having a controller is we can set the speed of the motor and we can implement soft start and stopping. So when we apply power to the system, we slowly ramp up the motor. When we shut it down, we also slowly ramp it back down. Compared to an AC pump, when you apply power to it, it quickly starts up and there’s a real jerking motion of that motor as it starts to spin. That can cause stresses in your drop pipe and drop wire, as that starting effect is transferred all the way up your casing. Everything can vibrate.

That can cause issues with loose plumbing connections. It can also cause chafing of your drop wire against your well casing. So by implementing soft start, we can slow that all down. We don’t get that large torque, that large jerking motion, causing wear and tear on the system.