Choosing Metal Fittings

When plumbing your well pump, you’ll encounter three main varieties of metal plumbing fittings: brass, steel, and copper. Mike’s got all three, and today he’ll explain the advantages and disadvantages of each.

00:00 – Intro

01:11 – Copper and Electrolysis

02:00 – Brass

02:27 – Stainless Steel

03:03 – Water Quality Test Reports For more on plumbing

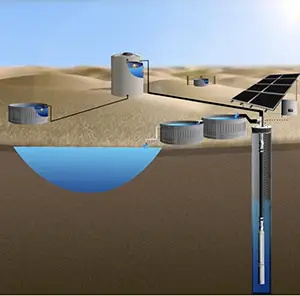

RPS Solar Pump Systems are for people that appreciate quality and value. Designed to aerospace standards, yet affordable. Easy to install. Zero maintenance. Zero energy costs. Quality you can trust for years and years to come. To learn more about wells, solar pumping and off grid systems visit our education center: https://www.rpssolarpumps.com/learn/ To shop solar pumps: https://shop.rpssolarpumps.com/ Just wanna talk? Give us a call at (888) 637-4493. We’re a friendly bunch. Shoot the breeze about your property, well or cattle, or get sized for a pump by our specialists at any time!

one of the most common questions we get asked is what type of metal fittings should you use in order to adapt from your pump outlet to whatever drop pipe you’re using this is mike with rps solar pumps and today i’m going to go over the pros and cons of using various metal fittings whether you’re thinking about using stainless steel copper or brass at rps all of our solar pumps feature stainless steel housings including outlets we chose that material for the longest lifetime because it’s the most corrosion resistance material for your deep well and surface pump applications a lot of wells are harsh environments they can be high in mineral content they can be acidic they can be basic and stainless steel is going to hold up the longest over the years when you go from the outlet of your pump to your drop pipe there’s a couple of different metal choices people consider that are available at your local hardware store we have copper fittings

we have brass fittings then we also have stainless steel fittings if at all possible we recommend to use stainless steel fittings to match the material of your pump outlet the reason to do that has to do with what’s called electrolysis so when we have two dissimilar metals in contact with each other let’s say this piece of copper and our piece of stainless steel when they’re attached together the dissimilar metals in a moisture-rich environment actually have an electrical current that goes between them and that can cause a lot of corrosion usually with the more active material now copper is a very active material and so it’s going to react with the well water it’s going to react with the stainless it’s going to try to react with whatever you whatever it has available that’s like with a copper penny while they turn green we don’t recommend using copper fittings with the pumps that’s going to corrode and you’re going to end up with problems really soon down the line possibly in a couple of years if you don’t have stainless steel fittings available your next best is using brass fittings when we’re doing brass fittings we’re going to want to minimize the number of transitions from stainless steel to brass so if you are doing brass fittings you’ll want to do the one transition out of your pump and then go to whatever other brass fittings you need to do down the line with the final transition to your drop pipe that’s going to minimize the amount of contact points where we have dissimilar metals and increased oxidation rates so if at all possible we do recommend getting stainless steel fittings good news we carry all of the hard to find stainless steel fittings so if you need one you can give us a call and we can help get you set up with the proper connections now if you’re out in the field and you only have a local hardware store very likely they aren’t going to carry this stainless steel and in that case it is okay to use the brass fittings if you’re using the brass fittings you just have to be aware you might have extra corrosion and may have to replace it in 10 years time versus say like 20 years time with all stainless steel but brass are more commonly available and they’re actually used throughout the whole well industry because stainless is much harder and much more expensive to find if you’re concerned about corrosion then it’s always good to get a water quality test report that test report will tell you the amount of hardness in your water the ph of your water and a lot of other details related to what’s called free ions now free ions in your water are what cause the corrosion in the harsh environment if you have relatively low calcium if your ph is relatively neutral then you can probably get away with using the brass fittings if you’re curious on what all these different fittings are we actually produced a great plumbing video for solar well pumps that goes over all the various connections you can check it out in the description below if you’re just not sure or you want to make sure your pump’s going to last as long as possible then go with our stainless steel fittings we have them in various sizes so you can give us a call at 888-637-4493 and we can help go transition from your pump end to your poly pipe and get you set up with all of the stainless steel fittings you need

Are you looking for a solar pump?

RPS is a family-owned company of laser-focused mechanical, electrical and software engineers that live and breathe solar pumping almost every hour of every day. We have sales offices in a number of states now, but our main shop has moved to an Ag town in California (we do get poked fun of for this!) and our warehouse to move there shortly. We put great time, money and thought into our kits – including parts and components to make installation a breeze. Our reading materials, manuals, videos and diagrams allow customers of all skill levels to install a solar pump successfully the first time. As has become famous, we also offer a direct line to talk with real humans! ..our actual pump engineers for asking questions, helping troubleshoot, or planning for installation.